Building the Future of Biotechnology, Semiconductors & National Defense R&D

A 280,000+ sq ft innovation campus uniting GMP biotech, semiconductor pilot fabs, and defense microelectronics under one secure ecosystem.

BioDeCTech’s integrated GMP–semiconductor–defense campus directly supports national initiatives in biomedical security, semiconductor resilience, and defense microelectronics innovation.

Building A – Biotech GMP → Building B – Semiconductors → Building C – Defense Microelectronics

Building the Future of

Biotechnology, Semiconductors & Defense

A 280,000+ sq ft national innovation campus — three multi-level facilities uniting ISO/GMP biotech labs, semiconductor pilot fabs, and SCIF-ready defense microelectronics.

Explore the Campus Request NDA / Data Room

Campus Includes

🧬 National GMP Biotech Center (Functional Scope)

ISO 1–8 GMP cleanrooms • cGMP diagnostics & manufacturing • BSL-supported QC/QA.

⚙️ Next-Gen Semiconductor Hub (Functional Scope)

ISO 1–6 cleanrooms • Advanced packaging & pilot fab • AI/quantum hardware R&D.

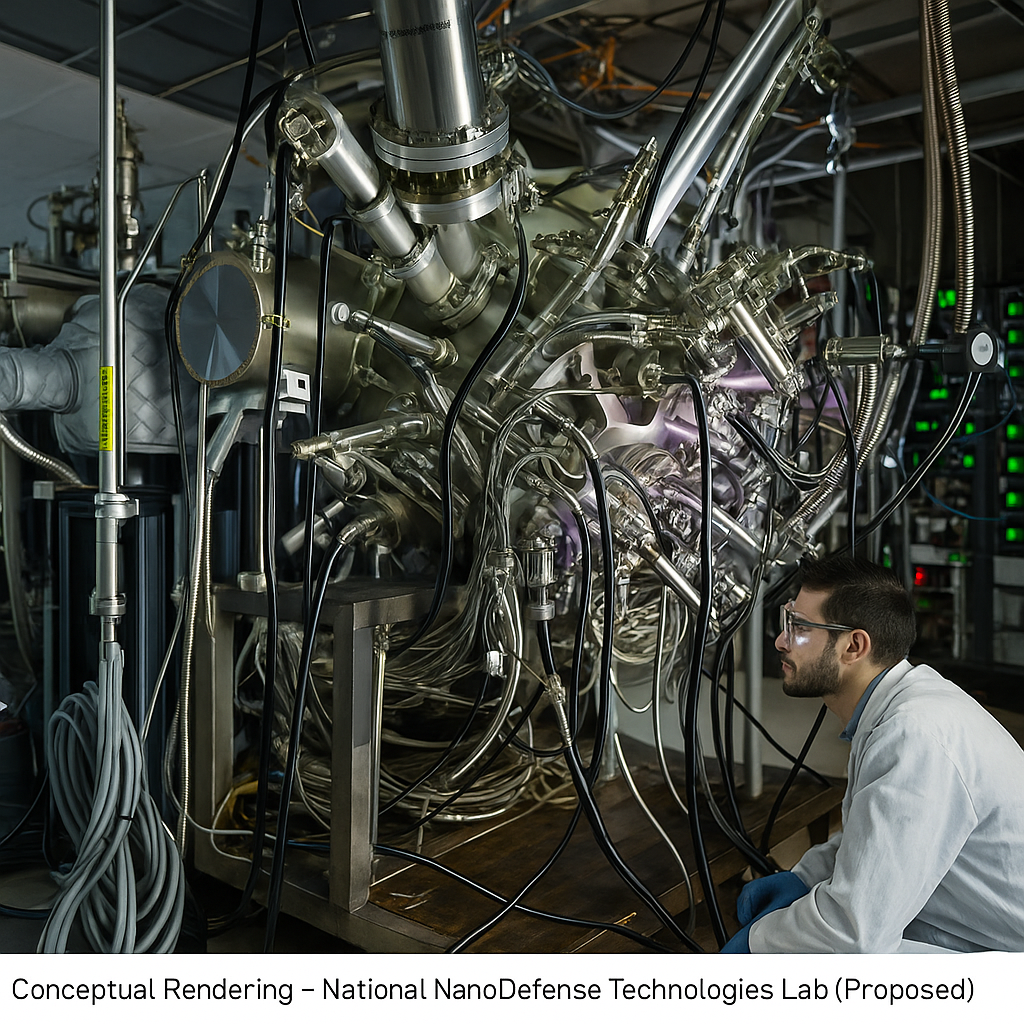

🛡️ National NanoDefense Technologies (Functional Scope)

ISO 1–5 nanofab zones • SCIF-ready microelectronics • sensors & secure AI hardware.

Integrated GMP + ISO Ecosystem

- ISO 1–8 suites with pressure cascades, HEPA/ULPA filtration, and environmental monitoring.

- BSL-supported labs and QC/QA suites for translational biotech and regulated manufacturing.

- Tool bays for lithography, deposition, metrology, packaging, and reliability testing.

- Hardened, SCIF-ready envelope and secure networks for defense microelectronics programs.

Federal & State Program Alignment

Readiness for Near-Term Obligation

Phase 1 — Building A (Biotech) is Shovel-Ready

- CGU (Change-of-Use) path identified; scope enables rehabilitation + vertical expansion.

- Utilities / MEP envelopes pre-matched for ISO 1–8 suites; dedicated QC/QA and BSL support.

- Site control and 99-year campus governance enable long-term federal programming.

- Schedule: Phase 1 procurement can commence within the near term upon award.

Capabilities & Compliance Matrix

Biotech: 1–8 • Semiconductors: 1–6 • Defense/Nano: 1–5

Biotech: Yes • Semiconductors: N/A • Defense/Nano: Yes

Biotech: N/A • Semiconductors: N/A • Defense/Nano: Yes

Integrated across tracks

FedRAMP-aligned networks (Bio) • Segmented/Zero-Trust (Semi) • SCIF protocols (Defense)

Bio manufacturing • Packaging & tool • Secure microelectronics

Workforce, Partners & Impact

Workforce Development

- Stackable credentials in GMP biotech, advanced packaging, and trusted microelectronics.

- Apprenticeships with local colleges and veteran pipelines; priority for underserved communities.

- Annual training target: 250+ seats across three tracks.

Economic & Equity Impact

- Direct jobs: 350–500 across phases; induced jobs via suppliers and services.

- Small-biz set-asides: goals for MBE/WBE/VBE participation in procurement.

Phased Roadmap

Partner with America’s Next-Gen Innovation Campus

*3D CAD rendering in production.

Biotech Capabilities

Semiconductor Capabilities

Defense Microelectronics & Nano

Strategic Location

Located within the Washington–Maryland Innovation Corridor, just minutes from Washington, DC — strategically positioned near major research and defense agencies. (Exact address undisclosed for security.)

GMP + ISO Cleanrooms

ISO 1–8 suites, pressure cascades, HEPA/ULPA, BSL-ready QC/QA.

Semiconductor Pilot Fab

Advanced packaging, lithography, deposition, metrology, reliability.

Defense Microelectronics

SCIF-ready envelope, secure networks, sensors & AI hardware.

Program Alignment

NIH • BARDA • CHIPS Act • DOE • NIST • DoD • DIU • DARPA.

Phased Roadmap

Phase 1: Building A (GMP). Phase 2: Building B (Semis). Phase 3: Building C (Defense).

Strategic Location

Washington–Maryland corridor — minutes to DC & federal agencies.

Innovating Tomorrow

BioDeCTech is at the forefront of biotechnology, semiconductor, and defense research, creating a national innovation campus for advanced development and collaboration.

BioDeCTech is strategically positioned within the Washington–Maryland Innovation Corridor — just minutes from Washington, DC and major federal R&D hubs.

Our proximity to NIH, BARDA, DOE, NIST, and DoD programs enables faster collaboration, easier access to funding, and secure engagement with government and industry partners.

Located approximately 15 minutes from downtown DC, the BioDeCTech campus offers accessibility, privacy, and room for next-generation growth.

Innovative Research Solutions

Our cleanroom facilities support ISO-certified processes for scalable biotech and semiconductor research, ensuring full GMP and federal compliance.